Gravity Capabilities

Ming Ming Aluminium Co., Ltd. holds fast to the T.O.R.S. (Top Quality, On-time Delivery, Reasonable Price, Sincere Service) principle in fulfilling every customer’s orders. To maintain our top quality, we also make sure that our casting procedure and objects are in line with international standards of IATF-16949 (formerly known as ISO/TS 16949), the quality management system for development, production, and services of automotive-related parts.

Parts and components produced in Ming Ming’s foundries go through a series of quality control inspections. Our quality control includes dimensional measurement, chemical composition analysis, mechanical properties testing, metallurgical analysis, and non-destructive testing.

What is the gravity die casting quality control at Ming Ming? It includes dimensional measurement, chemical composition analysis, mechanical properties testing, metallurgical analysis, and non-destructive testing.

Gauges SPECTRO optical emission spectroscopy metal analysers

Functions Analysis for determining the chemical composition of the metal.

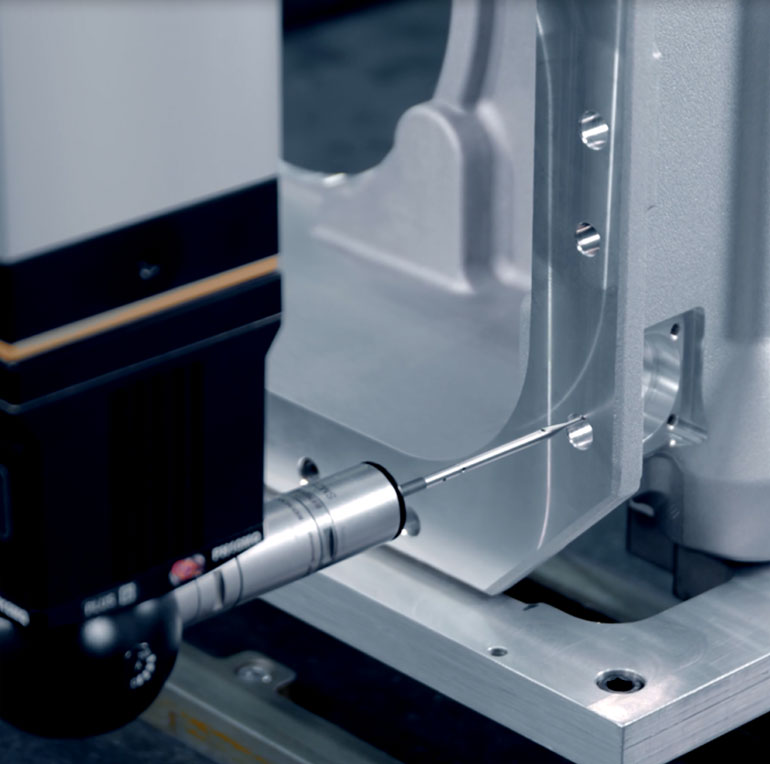

Gauges Height gage and coordinate measuring machines (CMM)

Functions Analysis for the cast’s or the sample’s dimensions and geometrical properties.

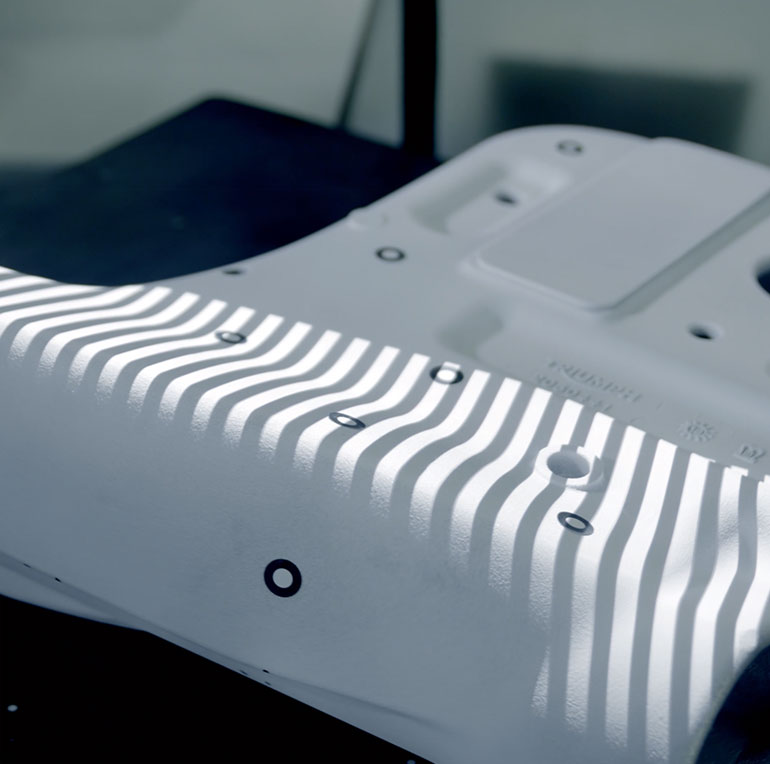

GaugesWhite light scanner

Functions Analysis for the cast’s or the sample’s surface height measurement and shape through 3D scanning.

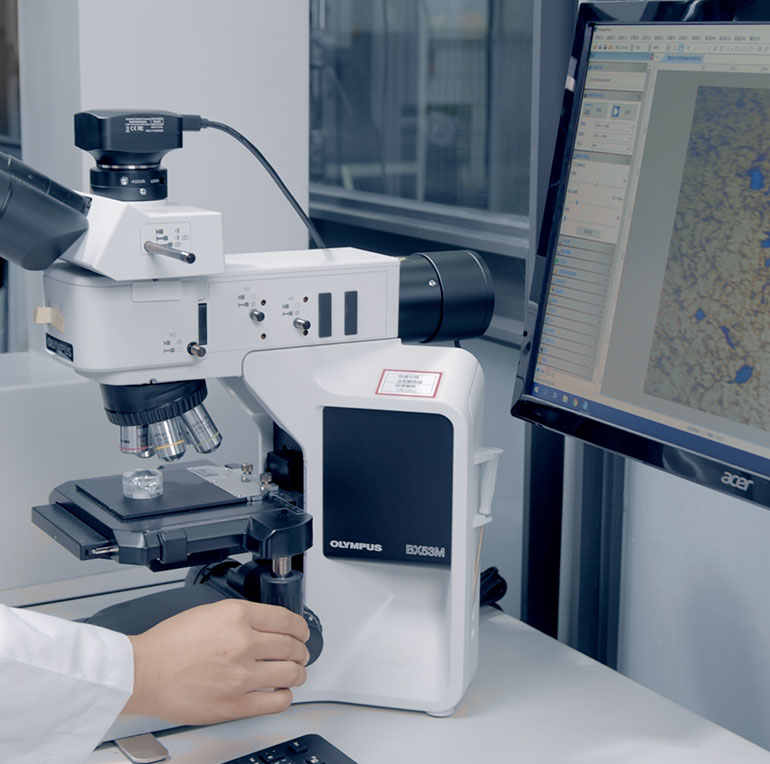

Gauges Metallographic analysers

Functions Analysis for the physical structure and components of the cast.

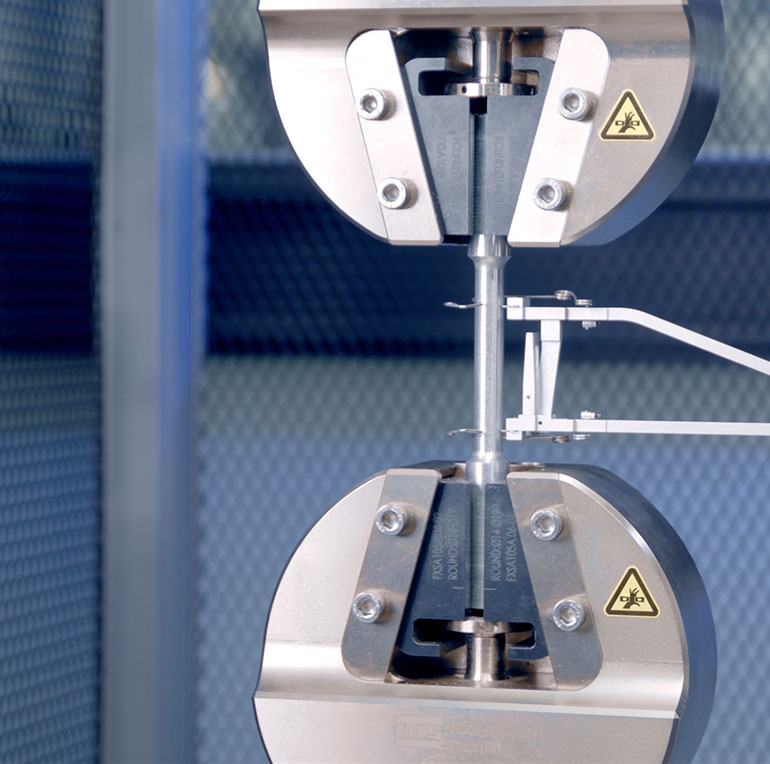

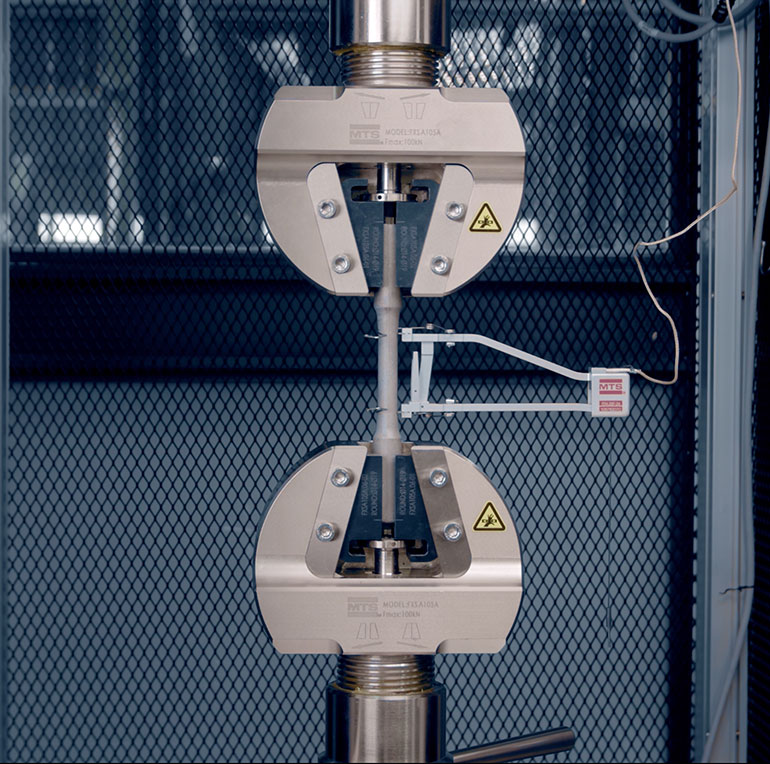

Gauges MTS systems

Functions Testing for a material’s structure and the response of a structure to a given action.

Gauges X-ray radiography test

Functions Analysis for evaluating cast properties without causing damage. Radiography is used for verifying the internal structure and integrity of the item.

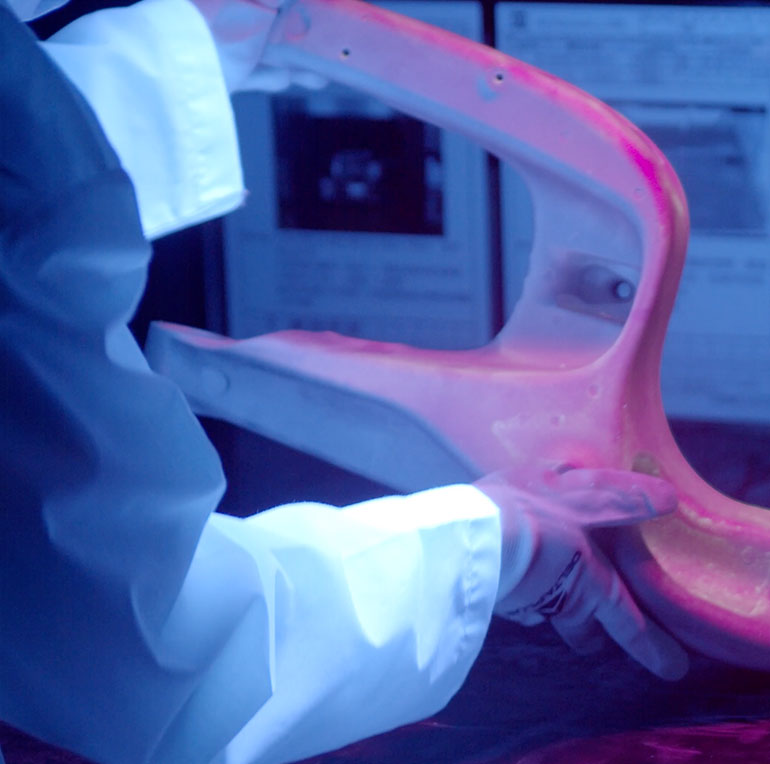

Gauges Dye penetrant test

Functions Analysis for evaluating cast properties without causing damage. Dye penetrant tests are for checking surface-breaking defects.