October 15, 2025

"The Devil is in the Details: How X-ray NDT Protects Your Casting Quality"

In Casting Quality Control, Both External and Internal Defects Are Critical In casting quality control, whether defects exist on the exterior or within the interior of a casting, both are key factors that influence quality. External defects can generally be detected visually, but internal defects require the use of high-energy X-rays for non-destructive testing (NDT).

In fact, in casting quality control, the most fatal threats are often not surface blemishes, but the hidden internal flaws invisible to the naked eye. X-ray NDT harnesses high-energy radiation to penetrate materials and convert density differences into images, effectively revealing porosity, shrinkage cavities, inclusions, cold shuts, and lack of fusion. This makes it especially suitable for critical components in aluminum re-casting and gravity casting.

What is X-ray Non-Destructive Testing (X-ray NDT)?

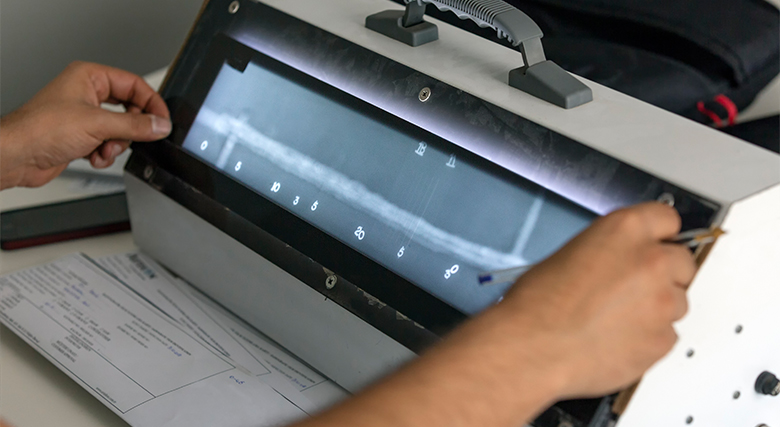

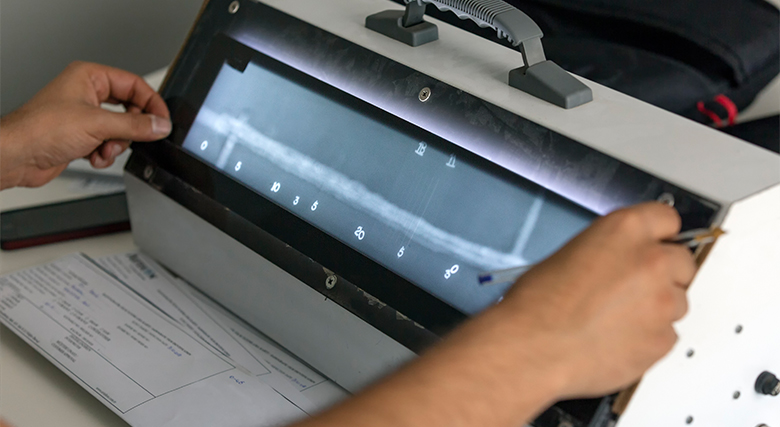

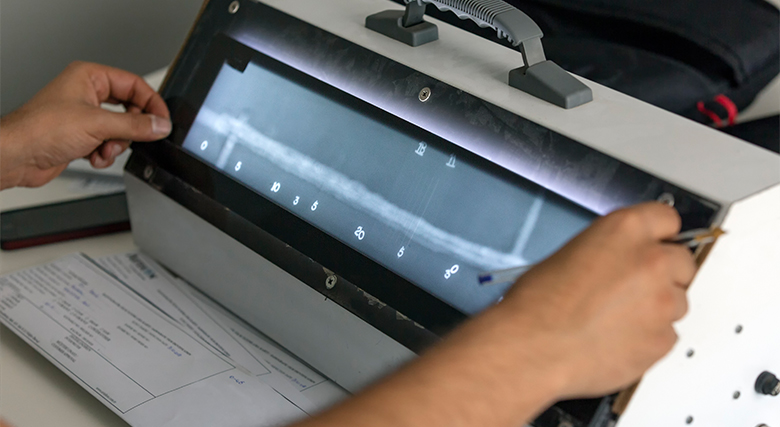

Non-Destructive Testing (NDT) is a method of evaluating the integrity of a material or component without damaging or affecting its future functionality. X-ray inspection works by exploiting the penetrating power of X-rays. When X-rays pass through a casting, their attenuation varies depending on material density, thickness, or internal defects (such as porosity, cracks, inclusions, or shrinkage voids).

The transmitted radiation is captured by X-ray film or a digital detector, producing grayscale images. From these images, engineers can identify the internal structure and potential defects in the casting.

The transmitted radiation is captured by X-ray film or a digital detector, producing grayscale images. From these images, engineers can identify the internal structure and potential defects in the casting.

Why is X-ray Inspection Important for Casting Quality Control?

For aluminum alloy components produced via gravity casting, even with stringent process control, internal defects can still occur due to factors such as metal solidification behavior, mold design, or operational variations. Common examples include:

- Porosity: Small gas bubbles trapped during solidification when gases fail to escape from the molten metal.

- Shrinkage: Cavities formed when molten metal contracts during solidification without sufficient feed metal to compensate.

- Inclusions: Entrapped non-metallic impurities within the casting.

In addition, X-ray inspection can be paired with specialized image analysis software to quantify defect size and distribution. This deeper insight enables engineers to better understand casting conditions and optimize production process management. Such stringent quality oversight reflects a company’s commitment to excellence, preventing products that fail to meet customer defect-grade standards from entering the market, thereby enhancing customer trust and satisfaction.

Conclusion

X-ray non-destructive testing is an indispensable tool for ensuring casting quality in the aluminum re-casting and gravity casting industries. Through high-precision internal flaw detection, it safeguards every detail, ensuring superior product performance and stable, reliable production levels.

| Prev Back Next |

Popular articles

How to Choose the Best Aluminum Alloy? Ming Ming Aluminium Explains the Properties and Applications of Gravity Casting Materials

"The Devil is in the Details: How X-ray NDT Protects Your Casting Quality"

Recycled Aluminum’s Carbon Footprint: Balancing Performance and ESG

GDC vs. HPDC Unlocked: Differences Between Gravity Die Casting and High-Pressure Die Casting, and When to Use Each

From Ground to Air: Gravity Casting’s Lightweighting Revolution in Robotic Arms and Drones

What is casting?

What is the difference between gravity casting and die casting?

What are the advantages of permanent mould casting and gravity casting?

What are the applications of gravity casting?

What is the process of gravity casting?

How does Ming Ming monitor gravity casting process and control quality?

What kind of materials are used for castings?

Do you provide any surface finishing service for castings?

What Is Prototyping?