October 15, 2025

From Ground to Air: Gravity Casting’s Lightweighting Revolution in Robotic Arms and Drones

The lightweighting revolution is accelerating—from the factory floor to aerial photography. Both robotic-arm components and drone parts demand lightweight designs together with high stiffness and dimensional stability. Ming Ming Aluminium Co., Ltd. combines gravity casting (including recycled-aluminum casting), topology optimization, and high-performance alloys to produce lightweight structural parts that deliver weight efficiency and stable dimensions.

Why lightweighting and high stiffness matter

For robotic arms, the mass of each joint directly affects payload capacity and dynamic response. Lighter components allow the arm to carry higher effective loads, reduce inertia, and improve motion precision and efficiency. High stiffness ensures the arm does not deform under high-speed motion or load, maintaining positioning accuracy.

For drones, a lightweight airframe is fundamental to longer flight endurance, improved flight stability, and greater payload capacity. Every gram saved matters. But lightweighting cannot compromise strength and safety; materials must provide an excellent strength-to-weight ratio and sufficient structural rigidity to withstand in-flight vibration and metal fatigue.

Why gravity casting is ideal for lightweight structural parts

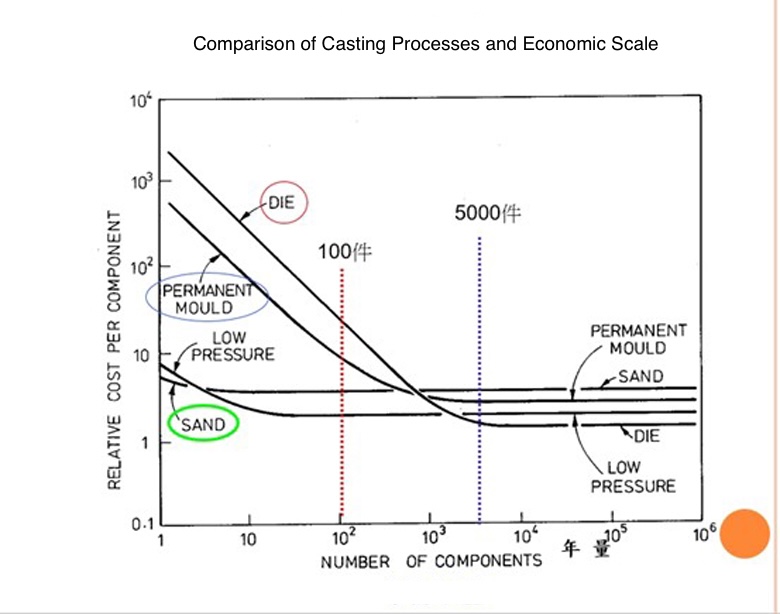

Among manufacturing methods, aluminum gravity casting stands out for meeting the needs of these high-tech industries. Compared with many other casting processes, gravity casting can deliver:

- Dense, uniform internal structure: Slow mold filling under gravity and gradual solidification reduce internal porosity and inclusions, producing a denser material that enhances mechanical performance—especially when alloys such as A356 and A357 are taken to their full potential with T6 heat treatment.

- Excellent mechanical properties: Castings exhibit high strength, hardness, and fatigue resistance to withstand complex loading conditions.

- Capability to form complex geometries: Gravity casting can produce intricate shapes with internal passages (for example, heat-dissipation channels or wiring routes), reducing downstream machining.

As automation and aerospace technologies advance rapidly, demand for lightweight, high-stiffness materials will continue to grow. Ming Ming Aluminium Co., Ltd. offers one-stop solutions—from DFM collaboration, finite-element and filling/solidification simulation, to heat treatment, precision machining, and surface finishing—ensuring each gravity-cast aluminum component achieves the best balance of cost, performance, and delivery.

| Introduction to Various (Aluminum Alloy) Casting Methods: | |||

|---|---|---|---|

| Casting Methods | illustrate | Accuracy | |

| 1 | Sand Mold Casting Water Glass (CO2) Casting Paste Mold Casting Lost Foam Casting |

Using Sand-Based Materials for Mold Materials: | Low |

| 2 | Lost Wax Casting Centrifugal Casting Continuous Casting |

Using Special Materials for Mold Materials: | High |

| 3 | High Pressure Die Casting Low Pressure Die Casting Semi-Solid Casting Forged Casting Gravity Die Casting |

Using Metal as Mold Material: | Medium |

| Comparison of Advantages and Disadvantages of Various Casting Methods | |||

|---|---|---|---|

| Casting Method | Advantages | Disadvantages | |

| 1 | Sand Molding | * Low-cost mold | * Relatively low dimensional accuracy |

| 2 | Die Casting | * Product yield 75–80% * Short production cycle * Can produce thin-walled castings * Requires little machining |

* Cannot use sand cores * Casting dimensions limited by machine capacity * Prone to porosity * Not suitable for small production runs |

| 3 | Gravity Die Casting | * Product yield 50–60% * Can use sand cores to produce complex parts |

* Relatively slow production speed |

| 4 | Low-Pressure Casting | * Very high product yield (approx. 90–98%) * Good dimensional accuracy |

* Must have directional solidification * High equipment cost |

| 5 | Lost-Wax Casting | * Smooth surface finish * Wide choice of metals * Wide choice of metals |

* Complex production process * Mechanical properties relatively lower |

| 6 | Lost-Foam Casting | * No need for draft angles in patterns * No sand cores required * Easy pattern fabrication |

* Mechanical properties relatively lower * CO₂ generated during pouring * Mold cavity cannot be inspected after pattern making |

| Comparison of Advantages and Disadvantages of Various Casting Methods | |||||

|---|---|---|---|---|---|

| Type | Minimum Weight | Minimum Thickness (mm) | Tolerance (±inch) | Labor Cost | Equipment Cost |

| Sand Mold | 30g | 3 | 0.2 | Medium | Low |

| Die Cast | 100g | 0.5 | 0.002 | Very Low | Very High |

| Heavy Cast | 100g | 2.5 | 0.015 | Low | Medium |

| Low Pressure | 100g | 2.5 | 0.015 | Low | High |

| Investment | 30g | 0.5 | 0.003 | High | Medium |

| Prev Back Next |

Popular articles

How to Choose the Best Aluminum Alloy? Ming Ming Aluminium Explains the Properties and Applications of Gravity Casting Materials

"The Devil is in the Details: How X-ray NDT Protects Your Casting Quality"

Recycled Aluminum’s Carbon Footprint: Balancing Performance and ESG

GDC vs. HPDC Unlocked: Differences Between Gravity Die Casting and High-Pressure Die Casting, and When to Use Each

From Ground to Air: Gravity Casting’s Lightweighting Revolution in Robotic Arms and Drones

What is casting?

What is the difference between gravity casting and die casting?

What are the advantages of permanent mould casting and gravity casting?

What are the applications of gravity casting?

What is the process of gravity casting?

How does Ming Ming monitor gravity casting process and control quality?

What kind of materials are used for castings?

Do you provide any surface finishing service for castings?

What Is Prototyping?